In the wave of smart factory construction, the congestion problem in warehousing and logistics has become a key bottleneck restricting the improvement of overall efficiency. Traditional warehousing management methods are difficult to meet the high demands of modern manufacturing for logistics efficiency, and the introduction of smart AGV carts is bringing revolutionary changes. 3D animation technology, as an advanced simulation and verification tool, is providing strong support for the planning, optimization, and demonstration of AGV systems.

Visualizing System Layout: Seamless Connection from Concept to Implementation

In the planning phase of smart warehousing systems, 3D animation can transform abstract layout plans into intuitive visual demonstrations. By establishing accurate 3D models of the factory, animation can simulate the operating status of AGV carts in real environments, including driving paths, obstacle avoidance logic, charging scheduling, and other full-process scenarios. This visual verification helps engineers identify potential problems before project implementation, optimize path planning, and avoid subsequent modification costs due to design flaws.

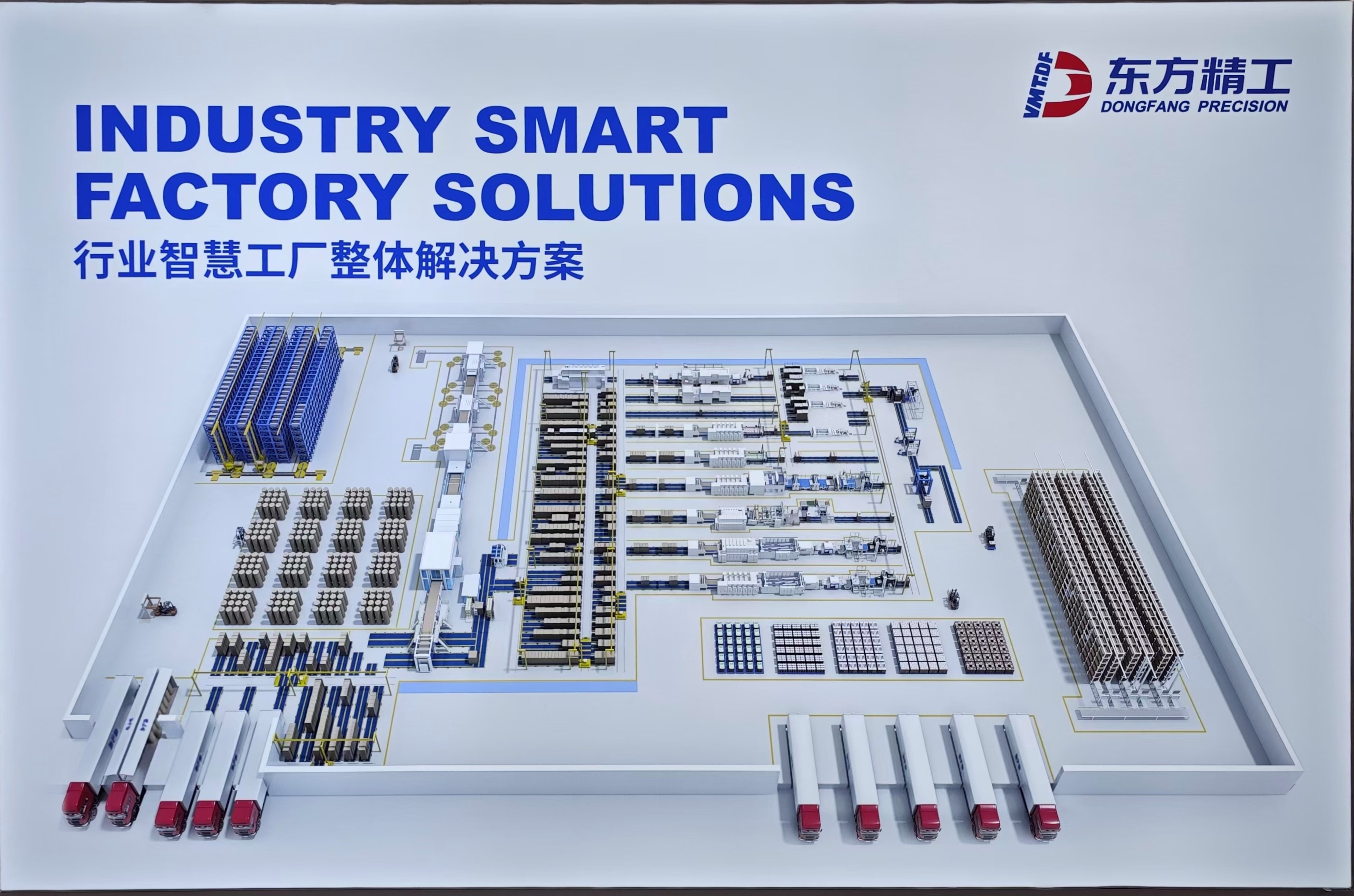

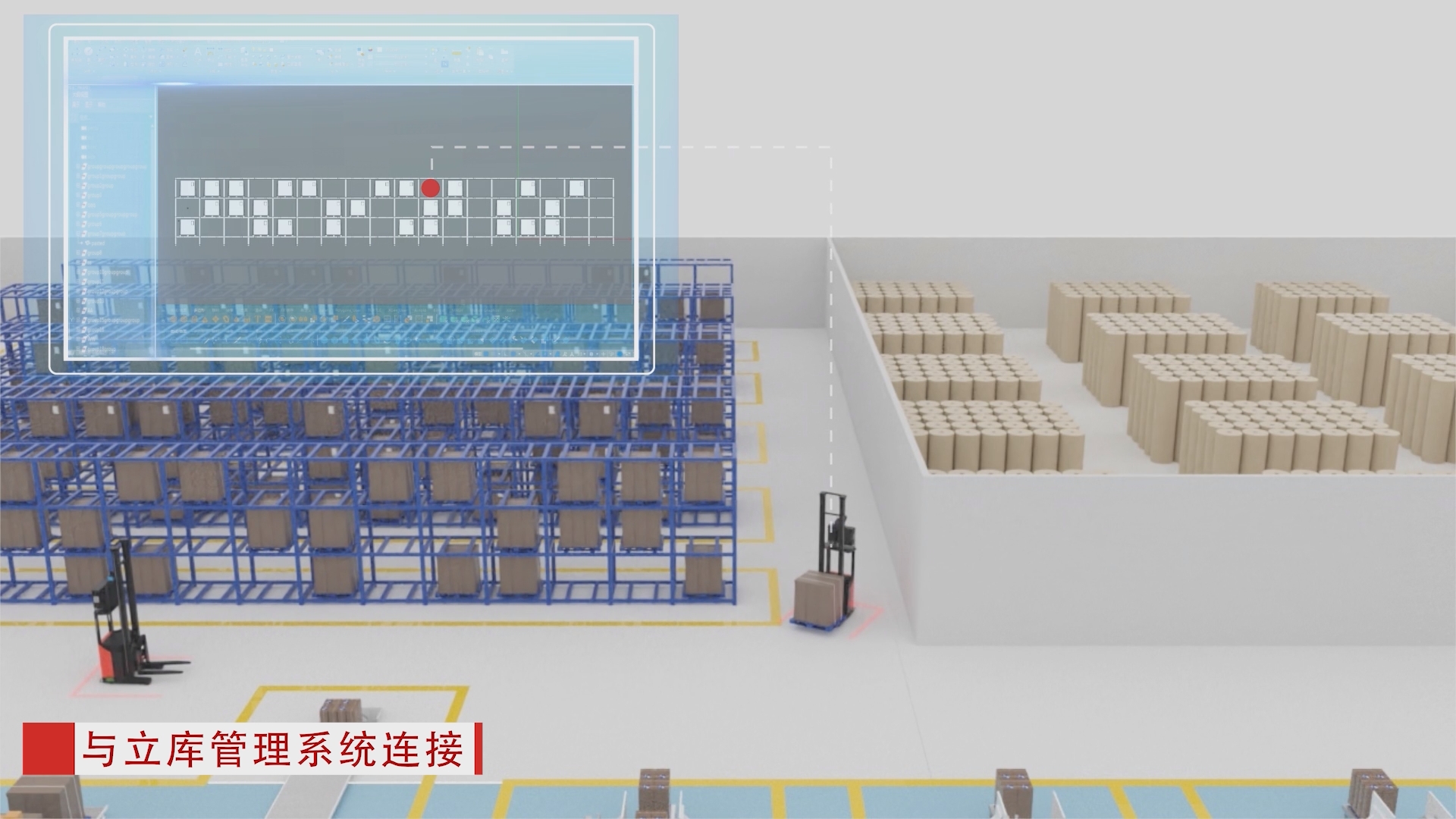

Guangdong Dongfang Precision Science and Technology Co., Ltd., in its smart factory project, presented the complete logistics process from raw paper warehousing to finished product outbound through 3D animation, clearly demonstrating the collaborative operation mode of AGV carts with automated high-bay warehouses, production lines, etc. This comprehensive visual presentation not only verified the rationality of the system design but also provided intuitive basis for project decision-making.

Dynamic Traffic Simulation: Predicting Bottlenecks and Optimizing Configuration

The power of 3D animation lies in its ability to perform dynamic traffic simulation, simulating the operating status of AGV systems under different workload intensities. By setting different peak order parameters, animation can intuitively display key indicators such as AGV cart scheduling efficiency, traffic congestion, and equipment utilization. This simulation capability allows planners to predict system bottlenecks in advance and optimize AGV quantity configuration and path planning solutions.

The IGV smart forklift animation by Fujian Fangguangshengshi Information Technology Co., Ltd. clearly presented the intelligent scheduling logic of multiple AGVs operating collaboratively through the visualization of system data acquisition. This dynamic simulation not only demonstrated equipment performance but also provided reliable capacity planning basis for clients, ensuring the system can meet future business growth needs.

Human-Machine Collaboration Safety: Reducing Operational Risks

In a smart warehousing environment, the safety of human-machine collaboration is crucial. 3D animation can simulate various scenarios of AGV interaction with personnel, verifying the effectiveness of safety protection measures. By demonstrating AGV's obstacle avoidance mechanisms, warning systems, and emergency braking functions through animation, it can ensure that the system design complies with safety regulations and reduces operational risks.

The smart logistics animation project by Fujian Fangguangshengshi Information Technology Co., Ltd. demonstrated the safety and reliability of the AGV system by simulating fault scenarios and emergency handling procedures. This visual safety verification not only enhanced the completeness of the system design but also provided vivid training material for operators, effectively reducing human operational errors.

Return on Investment Justification: Quantifying Value to Drive Decisions

For corporate decision-makers, the return on investment of smart AGV systems is a key consideration. 3D animation can quantify and display the benefits brought by AGV systems, such as efficiency improvement, labor savings, and error rate reduction, providing strong support for investment decisions. By comparing the operational efficiency of traditional warehousing models with smart AGV systems, animation can intuitively present the investment value.

A manufacturing enterprise showed through 3D animation simulation that after introducing the AGV system, material handling efficiency increased by about 40%, labor costs decreased by 30%, and warehouse space utilization increased by 25%. These visualized data strongly supported the investment decision, helping the enterprise accurately assess the project's payback period.

Continuous Optimization Support: Adapting to Business Changes

The value of smart AGV systems lies not only in their initial construction but also in their continuous optimization capabilities. 3D animation can serve as an experimental platform for system optimization, finding optimal solutions by simulating different operational strategies and scheduling algorithms. When business needs change, adjustment plans can be verified first in the animation model to ensure their effectiveness.

The smart factory animation project by Xiamen Huisite Intelligent Technology Co., Ltd. achieved real-time interaction between the physical system and the virtual model by establishing a digital twin model. This technology allows enterprises to continuously optimize AGV system performance, adapt to changing business needs, and maximize return on investment.

Future Outlook: Digital Twins Empowering Smart Warehousing

With the development of technology, 3D animation is evolving towards digital twins. Future AGV systems will achieve real-time mapping between the physical and virtual worlds, monitoring system operating status through 3D visual interfaces, performing predictive maintenance on equipment, and intelligently optimizing operational processes. This technological integration will further enhance the automation level and intelligent decision-making capabilities of smart warehousing systems.

The combination of smart AGV systems and 3D animation technology is providing innovative solutions for the manufacturing industry to address warehousing congestion issues. From system planning to operational optimization, 3D animation plays an indispensable role at every stage, helping enterprises build efficient, intelligent, and reliable logistics systems, and ultimately achieving digital transformation in warehousing operations.

Selected FAQs:

Q: What are the application areas of industrial animation?

A: Industrial animation is widely used in machinery and equipment, energy and transportation, home appliances, building security, bridges and tunnels, as well as in after-sales services such as product operation, usage, and maintenance.

Application scenarios of industrial animation include: exhibition demonstrations, product sales, new factory planning, after-sales service, engineering bidding, achievement reporting, education and training, advertising and marketing, equipment maintenance, etc.

Q: What kind of equipment (products) are suitable for creating live-action + 3D animation videos?

A: Live-action combined with 3D animation is a good way to showcase products and is suitable for most machinery, equipment, and industrial products.

Suitable for live-action combined with 3D animation presentation are: 1. Fast and efficient production machinery; 2. Highly intelligent and automated products; 3. Clean and tidy production sites, etc.

Situations not suitable for live-action filming: 1. Messy shooting environment, dim lighting; 2. Live-action makes it difficult to highlight equipment features (e.g., delicate fine-tuning movements, internal structure of the equipment); 3. Standalone components (the best presentation is to demonstrate their function and role alongside the complete machine).

Q: How to produce smart factory animation videos?

A: The production of smart factory animation videos should pay attention to the following points:

1. Preliminary Communication: In-depth communication is required from both parties in the early stages. The client should be very clear about the content and information the video aims to convey;

2. Script and Copywriting: Both parties confirm the script and copywriting before production, and key shots should also be determined if necessary;

3. Provide Complete Models: Smart factories involve many machines and equipment, requiring complete equipment models. If the client cannot provide complete models, they should provide pictures of the equipment for modeling (multiple angles);

4. Sufficient Production Cycle: The production cycle for smart factory animation videos is generally long. The client should reserve sufficient production time before starting.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startups, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for machinery and equipment, high-tech, software development, foreign trade companies, etc. We offer one-stop industrial 3D animation creative services from product sales to after-sales maintenance.

Provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding into overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in astonishing 3D animation. This not only brings a unique visual experience to clients but also quickly captivates their hearts.